IPM(Integrated Petroleum Modelling) Suite- Applied Production and Facilities Engineering-Fundamentals

In Reservoir and Production TechnologiesAbout this course

This course covers the fundamentals of reservoir, production and facilities engineering. Participants will learn reservoir, production and facilities engineering based on the application of qualitative as well as applied analytical techniques.

Key reservoir engineering concepts such as reservoir drive mechanisms, volumetrics, petroleum fluid properties and recovery factors will be introduced as tools.

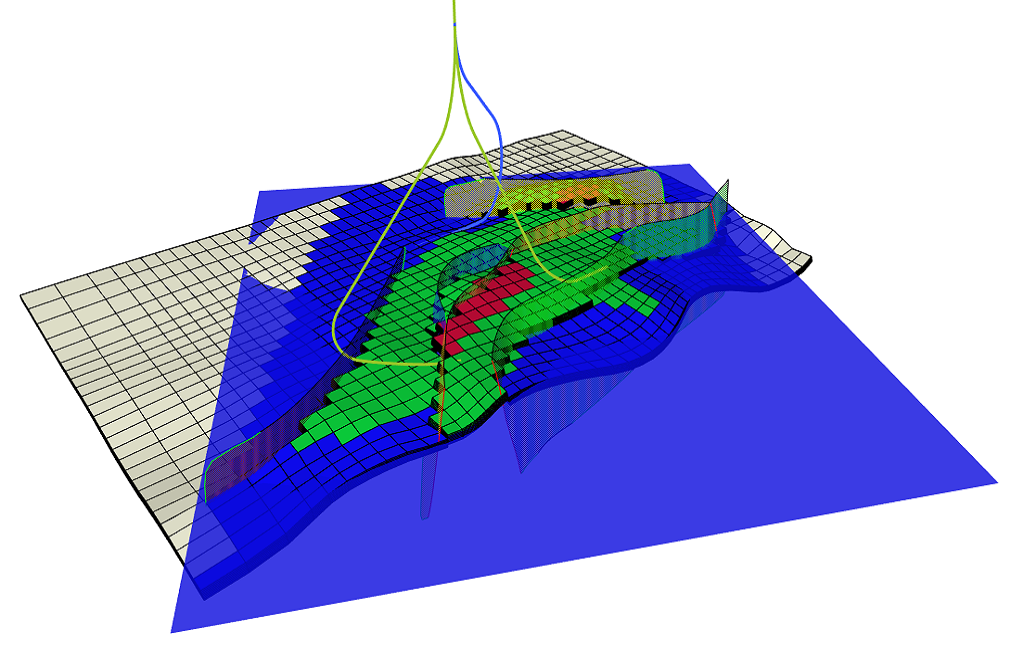

Reservoir modelling and simulations , forecasting and prediction of the production life cycle of the reservoir.

One third of the course will be “practicals and projects", which includes exercises and group discussions using MBAL software in IPM suite.

Participants will be given a brief introduction to the reservoir engineering as the course and what they can expect.

During this day fundamentals of reservoir phase behavior and fluid flow will be discussed. Participants will also be introduced to Darcy’s Law.

Participants will learn decline curve analysis and material balance concepts. They will also be discussing the principles of well testing during this day.

Participants will also learn about the development of the diffusivity equation and how to use it.

With Production Engineering Kit- IPM Prosper;

Key production engineering concepts such as well modelling, well production optimization, nodal analysis, sensitivity analysis, artificial lift system modelling, well completion methods, reservoir inflow performance, vertical lift performance ,flow correlations in different types of wells will be technically covered.

One third of the course will be “practicals and projects", which includes exercises, and group discussions using Prosper software in IPM suite. Participants will be given a brief introduction to petroleum production engineering as the course and what they can expect. During this day fundamentals of reservoir deliverability and fluid flow through the near wellbore zone and factors the affect its deliverability will be discussed. Participants will also be introduced to Darcy’s Law, vogels equations as the modes to use while predicting flow through both saturated and undersaturated reservoirs.

Participants will learn how to do PVT matching to determine the best flow corrections of fluids flow in the wellbore/. They will also be discussing the principles of well testing during this day. Participants will also learn about the field development plan and how to achieve the production profiles of the field.

Fluid compositional modelling, forecasting and prediction of the production life cycle of the well.

With facilities engineering kit- IPM GAP;

Key facilities engineering concepts such as surface facilities modelling, pressure drop calculations, fluid flow assurance, pigging process, field modelling and field forecasting and prediction of its production life cycle will be discussed technically.

One third of the course will be “practicals and projects", which includes exercises, and group discussions using GAP software in IPM suite.

Participants will be given a brief introduction to the petroleum facilities engineering as the course and what they can expect.

Contents

- Petroleum reservoir Geology

- Rock and Fluid Properties

- Reservoir modelling and simulation

- Reservoir and well deliverability

- History and PVT matching

- Fluid compositional modelling

- Well modelling and production optimization

- Artificial lift system modelling

- Surface facilities modelling

- Field production performance analysis

- Case study and Project on field development

Audience:

Course is designed for production and facilities engineers, Petrophysicists working in the oil and gas industry. Other students and professionals pursuing engineering, applied math and other natural and physical sciences are encouraged to apply.

Total Duration:

PDHs: 25 Hours (2.5 CEUs)- 2 weeks

Comments (0)